Home I RAYI

Home I RAYI

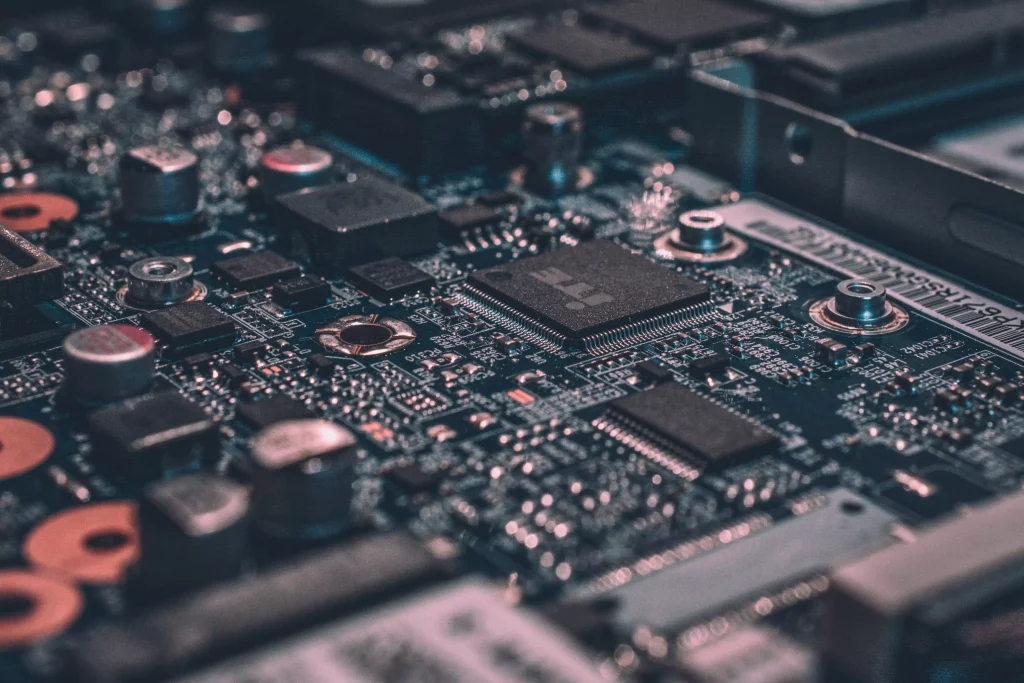

In the age of Industry 4.0, manufacturers are under increasing pressure to enhance productivity, improve quality, and reduce operational costs. Achieving these goals demands robust, real-time data processing and intelligent automation at every stage of production. However, traditional centralized systems often struggle to deliver the speed, flexibility, and integration required by modern smart factories. Compact, power-efficient edge AI solutions are emerging as a key enabler for next-generation manufacturing, allowing intelligence to be deployed directly at the source of data-on the production floor. RayI exemplifies this new class of technology, offering manufacturers a transformative approach to machine vision and AI-driven automation.

✅ Centralized Processing and Latency – Traditional machine vision systems in manufacturing rely on centralized servers or cloud platforms for image processing and AI analytics. This requires high-resolution video streams to be transmitted over networks to remote servers for analysis, introducing latency. Such delays can be critical when real-time defect detection or robotic guidance is needed.

✅ Bandwidth and Infrastructure Costs – Continuously transmitting large volumes of video data to the cloud or data center consumes significant bandwidth and increases operational costs. Network outages or congestion can disrupt production, reducing system reliability.

✅ Integration Complexity – Many factories are equipped with outdated machinery and fragmented IT infrastructure. Integrating new AI-powered vision systems (e.g., PLC, SCADA) often requires custom interfaces and significant downtime for installation.

✅ Limited Scalability – Expanding traditional vision systems across multiple production lines or factories is costly, as each deployment requires additional server capacity, network upgrades, and complex configurations.

✅ Slow Response Time – When defects or anomalies are detected, the processing and communication delays may lead to more defective products being produced before corrective action is taken, impacting yield and quality.

🔹 On-Device AI Processing – RayI integrates a high-performance processor with 6 TOPS or more and a Full HD camera within a compact size (47 × 47 × 35 mm). It performs defect detection, object recognition, and robotic guidance locally, eliminating cloud dependency and significantly reducing latency.

🔹 Reduced Bandwidth Requirements – Since data analysis occurs on-device, only actionable results (e.g., defect alerts, object counts) are transmitted, significantly decreasing data traffic and freeing up network bandwidth.

🔹 Seamless Integration and Flexible Deployment – RayI supports various connectivity options (USB, HDMI, Wi-Fi) and can easily integrate into existing manufacturing systems. Its compact design allows for retrofitting onto legacy equipment or installation in confined spaces without major infrastructure modifications.

🔹 Distributed and Scalable – Each RayI device operates independently, allowing manufacturers to deploy dozens or hundreds of units across multiple lines and facilities without overhauling central IT infrastructure. This distributed approach makes scaling simple and cost-effective.

🔹 Instant Feedback and Quality Control – Edge-based AI enables RayI to provide instant alerts and actionable insights, allowing operators or automated systems to halt production, sort out defective items, or adjust processes in real time—improving yield and reducing waste.

✅ Traditional System – High-resolution cameras capture images of each PCB, sending them to a remote server for defect analysis. Due to network lag, it takes several seconds for results to return. If a defect is detected, several more faulty boards may have already passed down the line before corrective action is taken. Integration with legacy PLCs is cumbersome, and scaling to new lines requires significant IT investment.

✅ RayI Solution – RayI is mounted directly above the conveyor belt, analyzing each PCB in real time as it passes by. It uses on-device AI to detect missing components, soldering defects, or misalignments. Once a defect is identified, RayI immediately signals the line’s PLC to stop the conveyor or divert the defective board, minimizing rework and scrap. Only summary data and alerts are sent to the central dashboard, reducing network load. Expanding to additional lines is as simple as installing more RayI units.

RayI revolutionizes manufacturing by deploying high-performance AI vision systems at the edge. It fundamentally addresses the challenges of latency, bandwidth, integration, scalability, and response time that traditional centralized systems face, enabling smarter, more agile, and cost-effective production management—driving the progress of Industry 4.0.